Forstner nuSLIT

Programmable slitting line

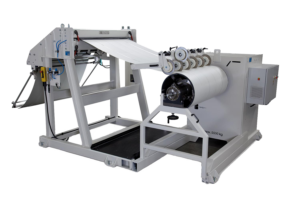

The nuSLIT is the perfect system for a future-oriented company. It combines easy handling of slitting jobs with an unprecedented leap in innovation. The 5 sets of slitting knives supplied as standard are arranged alternately, this guarantees twist-free slitting results even with narrow slitting widths. The pairs of knives are individually positioned by a linear guide carriage and at the same time the cutting gap will be perfectly adjusted to the sheet metal. After all knives are in the programmed position, the knives are clamped with a sophisticated clamping system integrated in the shaft. The nuSLIT does not use any hydraulic components, which would be very maintenance-intensive and inefficient. Thanks to this innovation, our customers can count on low maintenance costs. Another cost saving is the knives themselves, because they can be turned and resharpened, which significantly extends the life of a set of knives.

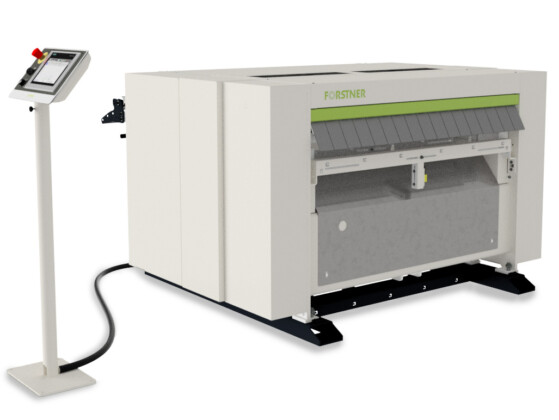

F3-Control

The F3-Control has a variable speed setting and 20 programm lines. The operator can program the material, the length, the straightening setting and the number of parts to be cut. Due to the motorised raising and lowering of the slitting blades, there is no waste at the end of the job.

All drives, motors and encoders are from the reliable Siemens brand. The simple icon display makes operation easy for all languages.

Another feature of the F3-Control of the nuSLIT – Series is the fully automatic straightening. The operator specifies the straightening value in the material table, the remaining calculation and control of the straightening shafts is done by the control system.

6 STRAIGHTENING ROLLERS

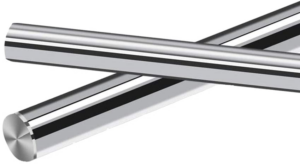

Optionally, your nuSLIT can be equipped with 6 automatic straightening rollers that remove coil set and cut an optimally straightened sheet. The rollers are made of polished steel with a diameter of 70 mm. The pressure of the straightening rollers is adjusted by the control system. The calculation of the straightening roll depth is done from the material table.

The Forstner nuSLIT Series makes all your dreams come true, in a modern sheet metal workshop and takes your production to a new level consider flexibility and productivity. With nuSLIT every function can be operated from the touch panel: coil width, finished lengths, straightening pressure to avoid stop marks, the width settings and operation of the slitting knives. nuSLIT can be integrated in a programmed production flow. The control system is totally compatible with nuIT, allowing you to plan and program your entire production from your office desk with no manual intervention. Combine with the number of decoilers you want and a manual or powered coil selector. There isn’t a better slitting and cut-to-length machine on the market!

The most important advantages:

- Alternating knife arrangement

- Unbeatable slitting precision

- Innovative clamping system

- Control system can be integrated with nuIT

- Fastest knife change on the market

| Specifications | |||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Machine | Type | Working width | Straightening rolls Ø | Slitting capacity Steel 400 N/mm² |

Slitting capacity Stainless 600 N/mm² |

Slitting shaft Ø |

Slitting knives | Speed | Shear | ||||||||||||||||||||||||||||||||||||||||

| ” (mm) | mm | ga (mm) | ” (mm) | ” (mm) | pair | m/min | |||||||||||||||||||||||||||||||||||||||||||

| nuSLIT PRO 1250 | Aut. Slit & Cut-to-length | 50″ (1250mm) | — | 20ga (1mm) | 24ga (0.6mm) | 4.17″ (106mm) | 5 | 25 | Guillotine shear | ||||||||||||||||||||||||||||||||||||||||

| nuSLIT STRAIGHT PRO 1250 | Aut. Straightening Slit & Cut-to-length | 50″ (1250mm) | 70 | 20ga (1mm) | 24ga (0.6mm) | 4.17″ (106mm) | 5 | 25 | Guillotine shear | ||||||||||||||||||||||||||||||||||||||||

| nuSLIT PROCUT 1250 | Aut. Slit & Cut-to-length | 50″ (1250mm) | — | 20ga (1mm) | 24ga (0.6mm) | 4.17″ (106mm) | 5 | 25 | Sectional shear | ||||||||||||||||||||||||||||||||||||||||

| nuSLIT STRAIGHT PROCUT 1250 | Aut. Straightening, Slit & Cut-to-length | 50″ (1250mm) | 70 | 20ga (1mm) | 24ga (0.6mm) | 4.17″ (106mm) | 5 | 25 | Sectional shear | ||||||||||||||||||||||||||||||||||||||||

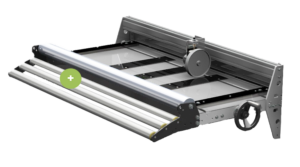

The infeed guide roller are angled to match the loop of the coil from a decoiler. This helps prevent creasing on soft materials like copper, aluminum and zinc.

The table guide has four roller bearings (two on each side) to guide the metal in the pinch rolls. The roller bearings allow the metal to move easily forward and backwards without damaging the edges. This also keeps the material straight as the material is fed into the machine helping to ensure a square cut.

The nuSLIT is the perfect system for a future-oriented company. It combines easy handling of slitting jobs with an unprecedented leap in innovation. The 5 sets of slitting knives supplied as standard are arranged alternately, this guarantees twist-free slitting results even with narrow slitting widths. The pairs of knives are individually positioned by a linear guide carriage and at the same time the cutting gap will be perfectly adjusted to the sheet metal. After all knives are in the programmed position, the knives are clamped with a sophisticated clamping system integrated in the shaft. The nuSLIT does not use any hydraulic components, which would be very maintenance-intensive and inefficient. Thanks to this innovation, our customers can count on low maintenance costs. Another cost saving is the knives themselves, because they can be turned and resharpened, which significantly extends the life of a set of knives.

The Guillotine shear will be the perfect solution for customer that are looking for a fast and smooth cutting process. The shear utilizes a high carbon blade for long lasting cuts, up to 1.5 mm Mild Steel (400N/mm²). The enforced shear frame ensures a smooth shearing motion.

The F3-Control has a variable speed setting and 20 programm lines. The operator can program the material, the length, the straightening setting and the number of parts to be cut. Due to the motorised raising and lowering of the slitting blades, there is no waste at the end of the job.

All drives, motors and encoders are from the reliable Siemens brand. The simple icon display makes operation easy for all languages.

Another feature of the F3-Control of the nuSLIT – Series is the fully automatic straightening. The operator specifies the straightening value in the material table, the remaining calculation and control of the straightening shafts is done by the control system.

The PROCUT is built on the platform of the PRO (guillotine shear), which makes the PROCUT impress with its robustness and durability. This is coupled with unsurpassed flexibility and precision. The PROCUT consists of a bottom mounted guillotine shear blade and a top mounted roller blade on a linear guided shear head. The PROCUT uses high carbon blades for long lasting quality cuts up to 1.00 mm steel (400N/mm²). This design allows partial cuts to be made on the sheet metal, your advantages are obvious. Minimum waste in combination with the highest cutting quality.

Another option for your nuSLIT is the labelling of the sheets. The PRINT extension brings you the perfect organisation of your parts, because each sheet is given an individual QR code that contains all the relevant information. This in combination with the Smart Factory software nuIT leaves nothing to be desired, scan the QR code on your folding machine and the bending geometry is transferred by nuIT. An error-free and precise way of working that makes your working day easier.

Optionally, your nuSLIT can be equipped with 6 automatic straightening rollers that remove coil set and cut an optimally straightened sheet. The rollers are made of polished steel with a diameter of 70 mm. The pressure of the straightening rollers is adjusted by the control system. The calculation of the straightening roll depth is done from the material table.

The film applicator can basically be mounted on any table. Using the deflection rollers and the fully rubberized feed rollers, the protective film is pressed on almost bubble and wrinkle-free. The device type F-AG z2mo has an additional arm with tension spring for tensioning the film during the return movement. This design is only applicable for single decoiling systems.

The nuSLIT Series are as standard equipped with 5 pairs of slitting blades (stainless steel version). You can add up to max 7 pairs of slitting blades.

The standard speed of nuSLIT series is 25 m/min. You can upgrade the speed to 35 m/min or 45 m/min.

The coil guide is an important component for the function and accuracy of every system. The table has a fixed and a manually adjustable coil guide with ball bearings. The adjustment of the movable coil guide is done by a hand wheel. This specific table has rollers integrated in the table to ensure a smooth surface.

For more demanding applications and a longer life span we recommend the hard chromed shafts on the straightener.

Choose from a simple cradle up to motorized versions. Read more under respectively product.

Add a foot switch to your nuSLIT machine for external start of next order.

If you want to prepare your line for a film applicator, then the option with the fully rubberized rollers is ideal for you. This means that your line is ideally prepared for retrofitting a film applicator at any time and with ease. Fully rubberized pinch rollers available in both 1250 and 1500 mm.

With this recoiler, slits or wide strips can be easily recoiled. The coils are wound tightly to a diameter of 508 mm and an optically clean coil is produced after wrapping and removal. The recoiler has a dancer arm, separating discs, a pneumatic felt brake, a motor and a hydraulic mandrel.